Devil Fish

mods

to the TB-303

TB-303 maintenance and simple modifications

2013-11-24 Robin Whittle

rw@firstpr.com.au

Here are some modifications and maintenance tips. Please

also

see the notes on spare parts in Q9 of the FAQ at the main Devil Fish

page.

To the main Devil Fish page.

An update history is at the end: #updates

.

This

information is for

people who already know about electronics and in particular about

avoiding static electricity damage to electronic equipment. If

you don't already know about static electricity and if you did not already know that it

can destroy components - including the CPU of the TB-303, for which

there is no replacement - then please get a competent technician to

work on your machine rather than doing it yourself.

Search engine bait: TB303 pots, TB-303 pots, TB 303 pots,

Bassline

pots, TB303 switches, TB-303 switches, TB 303 switches, Bassline

switches.

Contents

1 - Replacing the

tact switches with Omron B3W-4050 sealed tact switches

2 - Six small pots from Tuning to Accent

3.1 - Never spray anything in the machine

3.2 - Overheated Q45 power transistor

3.3 - Pinched wires during re-assembly

3.4 - Knobs falling off

3.5 - Noisy volume pot

3.6 - Batteries not connecting

3.7 - Memory problems - corrosion of RAM chip pins

3.8 - Buzzing due to LED activity

4.1 - Increasing the range of the Cut Off and Env

Mod pots

4.2 - Improving the bass response

Update history

1 - Replacing the tact

switches with Omron B3W-4050 sealed tact switches

#Omron_switches

These notes apply to the TB-303 and TR-606, but there are

also some

notes on similar switches which are used in the TR-808, JP-8 and the

original DX-7.

Please see ../tact-switches/ for

a comparison between the original ALPS unsealed tact switches, the

ALPS sealed tact switches and the Omron sealed tact switches.

The TB-303 has 24 "tact" (tactile) switches which were made by the

Japanese

company ALPS http://www.alps.com

who make the pots and rotary switches in the TB-303 and the miniature

pots

in the Devil Fish. These are good switches, but they are not sealed

against

dust.

Household dust, especially flakes of skin, get into the switch and

contaminate

the contacts, causing them to become unreliable. This can make the

TB-303

impossible to program. The original DX7 uses the same switches as

the TB-303 / TR-606.

However, they seem to last very well in the DX7, where they are well

protected from dust.

Until mid-2010 I replaced these switches with the same type, which

by 2010 were known as SKHCBEA010, but which were originally known as

SKHCAA. To protect the switches from dust, I installed a thin

plastic dust guard which covered the switches, but had holes for their

stems and for the nearby LEDs. This worked very well, but not

perfectly. Some machines which were used intensively needed their

switches replacing again after about 10 years.

One alternative is to use ALPS sealed tact switches:

SKQEAAA010. Based on my experience with 100 of these I ordered from the ALPS distributor here: http://www.switchesplus.com.au

I decided not to use these, because I found their click action to be

much weaker than that of the original ALPS unsealed switches and of the

Omron sealed switches. Please see the above-mentioned comparison

page for details

The only other suitable sealed tact switch I am aware of is the

Omron B3W-4050. Omron,

like ALPS, is a very highly respected

Japanese manufacturer. The Omron tact switch page had a very long

and perhaps not very permanent URL

in August 2010. Likewise the PDF datasheet, so I have archived a

copy of it

here: Omron-Tact-Switches-2010-B3W_1109.pdf

.

The

B3W-4050 has a stem almost like the original ALPS switches,

but the stem is unfortunately too wide for the TB-303 / TR-606

switches. (It is specified to be the same size: 3.8mm.

However, in reality it is too wide.) To replace the stemless switches

(originally known as

SKHCAB) in the TR-808 or JP-8 the B3W-4000 switch

would be one to use.

These Omron switches are available from Farnell / Newark. In

mid-2010, the Australian Farnell system had two entries for the

B3W-4050. One was for Australian stock and the other was for US

stock from Newark - with the Newark switches prices being about 1/3 of

the Australian stock's prices. The Farnell number for the

Newark-stocked switches is1436527. The Australian page

has an image of another type of tact switch.

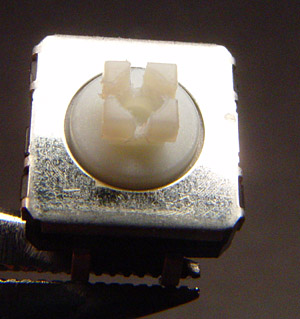

Modifying the Omron switches

The Omron switch stems are too wide for the TB-303 buttons. One

approach is to file them down - but this is very difficult, since the

stems are made from nylon or something similarly resistant to

filing. Another is to use a small, fine, but very fast grinding

wheel to shave a little off the four sides of the top of the

stem. Initially, this is what I did. I built a fancy jig to

enable me to do it reasonably reliably, but still I found it very

difficult to get the final dimensions correct. Doing this, it is

important to shave evenly, otherwise the button will be rotated

clockwise or anti-clockwise. I had quite a few rejects.

Part of the problem is that the holes in the TB-303 buttons vary

considerably. This may be partly due to molding differences, but

I suspect the main cause of variation is the different thicknesses of

copper plating underneath the chrome plating.

(By the way, the chrome plating on these buttons and knobs is

absolutely first-class. Many of these buttons and knobs have been

in frequent use for nearly 3 decades now, and are showing little or no

sign of wear. I don't know of any other button or knob which

lasts so long, and looks so good, no matter how much it is used.)

The solution is to cut the stem twice, at right-angles. This

doesn't reduce its outer dimensions, but makes it springy. There

are several advantages to this over trying to shave down the sides of

the stems:

- The cuts are non-critical in terms of thickness and

placement. Only the depth needs to be tightly controlled - just

to the bottom of the outer part of the stem, and not any further into

the neck of the stem. Shaving the sides down is extremely

critical, and requires even removal of about 25 microns from all 4

sides. This is thinner than human hair. The stems of the

ALPS switches are about 3.775mm and the stems of the Omron switches are

about 8.820mm.

- The cuts don't alter the outside of the top of the stem, so

there is no alteration of the button's rotational orientation on the

stem.

- The springiness which the cuts introduce into the stem makes

the stem fit very nicely into TB-303 buttons no matter what size their

holes.

It suffices to cut the Omron switch

stems by hand, with a Dremel tool or similar, with a 0.6mm cutting

disc. (The old Dremel cutting discs are a dull red or brown

colour.) It would be best to allow for some rejects with this

hand-held approach.

I adapted my original jig to do the cutting. I use a tiny metal

circular saw, with appropriate safety guards. If you already have

the Dremel saw attachment, that might be OK to use. Otherwise, I

suggest using a cutting wheel.

It takes me longer to remove the swarf from the cuts than to actually

make the cuts. I do this with a scalpel under a stereo

microscope. It is not necessary to remove all the swarf, since as

long as it remains attached inside the button, it can't do any

harm. Still, I try to remove the main pieces of swarf from the

two cuts. Most of the swarf is still attached because the plastic

partially melts during cutting.

Here are some photos:

Hopefully you will be able to obtain

Omron switches and cut them like

this. However, please see the Devil Fish page:

../#tact_switch_kits if you want to

purchase modified Omron switches from us.

Removing the old switches

When you dismantle the machine, you may want to keep it connected to

the

batteries (taped into its battery compartment) in order to retain the

memory

contents. Often the on-board capacitor will retain memory data for

days,

but it is probably best not to trust it when you are working on the

machine.

I suggest removing the buttons before desoldering the

switches. This can be tricky - I use very long pointy-nose pliers

to prise the buttons up evenly.

De-soldering the old switches is pretty straightforward. I use a

Weller vacuum de-soldering

station.

A second alternative is a standard soldering iron and a push-in,

press-to-release

solder sucker. The only problem with these is that the sucker may jump

forward

and damage tracks. A third alternative is to use solder-wick to soak up

the

excess solder.

Installing the new switches

This is easy – just solder them in.

2 - Replacing the 6 small pots from Tuning to Accent

#6_small-pots

Update 2013-11-24:

The pots described below are

not the ones currently being supplied by Technology Transplant.

They are now supplying the same pots which are used in the Cyclone

Analogic TT-303 Bass Bot. These pots are similar to those

described below, but their base is higher so the shaft height above the

PCB is correct. I don't know of any problems with the Resonance

pots becoming noisy in Bass Bots, so as far as I know these pots can be

used as they are supplied.

Soldering TB-303 and TR-606 pots is tricky. Once they are soldered in and the machine is ready to be reassembled, be prepared to heat the melt the joints and push the pots around a little so the shaft is close to the centre of the front panel hole.

Please see the page ../pot-wear/

for photos of how the original ALPS pots can fail due to being

turned while downwards pressure is applied to the shafts. This

causes the outside of the rotor to cut into the conductive

tracks. Earlier generation replacement pots from Technology

Transplant could fail in the same way.

In late 2009, Technology Transplant

http://www.technologytransplant.com

started selling another batch of

pots, which I think was their third or fourth batch. The first

one or two batches (the first was in 2002s, I recall) were dull zinc

plated.

The next batch (mid 2000s) was

yellow cadmium plated, and quite hard to solder. The cadmium

plated batch had a difficulty with the Resonance pot shaft being too

large for TB-303 knobs, so it was necessary to drill out the

knob. These Resonance pots were not linear - they had a log curve

at both ends. This is a minor problem, since it doesn't alter the

range of sounds, just which knob positions the sounds occur at.

Most of the pots in this cadmium plated batch, and I think most of

those in the earlier zinc plated batches, were also subject to the

problem of downwards pressure while turning causing the rotor to cut

into the conductive tracks. This was due to the design of the

pots which involved downwards pressure being taken by the outer part of

the rotor - so it id a design fault in the ALPS pots and most of the

earlier batches of TT replacement pots..

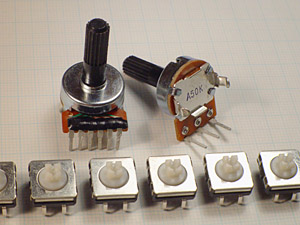

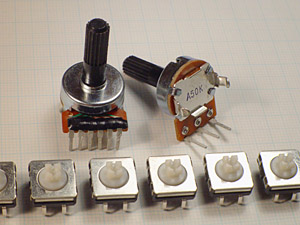

The late 2009, early 2010 batch of pots from Technology Transplant, as

pictured here:

is completely different from earlier batches and from the original ALPS

pots. These are bluish silvery plated and very easy to

solder. They are 17mm in diameter, which is marginally wider than

all the other types of pots - but this size is fine, they are not too

big.

The good news is:

- The shafts of all the pots

fit the knobs perfectly.

- None

of the pots are subject

to the failure mode of the rotor cutting the conductive tracks if the

shaft is turned while downwards pressure is applied. This was the

primary mode of failure of the ALPS pots. In these new pots, the

downwards pressure on the shaft is taken by the very end of the shaft,

which goes through a small hole in the phenolic board, and presses

against the steel back-plate - about in the middle of the "A50K" text

in the image above. This means the outer part of the rotor never

goes near the conductive tracks.

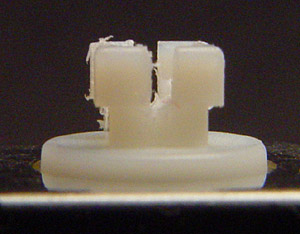

Here is a photo of the rotor and

phenolic board of the Resonance pot:

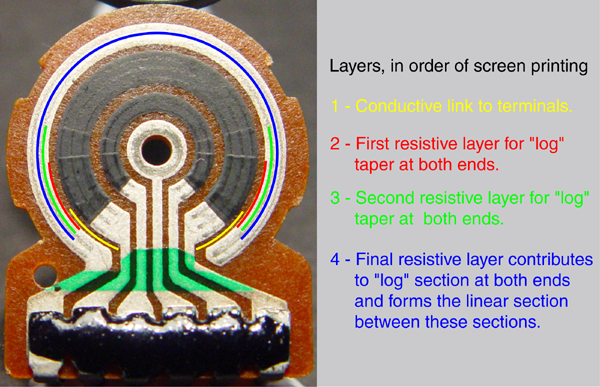

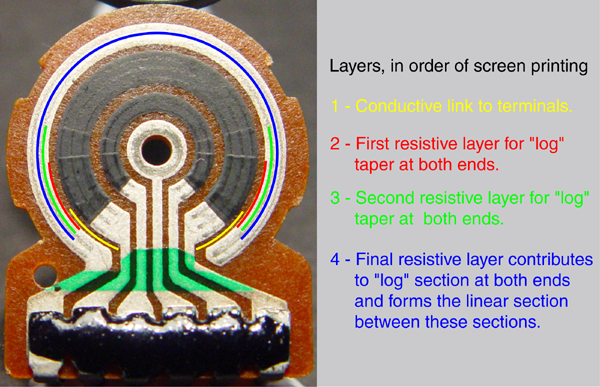

The central part of the shaft goes through the hole in the middle and

presses against the metal backplate. This takes all the downward

force applied to the shaft. The outer part of the rotor is not

close to the phenolic board, so it can never press against it or cut

the conductive tracks.

The black epoxy is to protect the riveted connections between the

conductive tracks and the terminal pins from corrosion.

There

are two remaining problems:

- The Resonance pot still has

the log curve at each end, rather than being linear. As noted above,

this nothing to worry about, since it just alters the knob

position for a given sound, rather than alters the sounds which are

available.

The photo below shows how the three resistive layers are printed, for

both sections of this dual pot.

- The shafts are about 1.6mm too

short. See the discussion below about what to do about

this. The

knobs on a TB-303 are already marginally too low. I have been

boosting

them up about 1.6mm for quite a few years. That technique - a

small

circle of leather inside the knob - could be applied to these pots to

restore the knobs to the original height, but it is not possible to

extend this technique to more than about 1.6mm.

I

understand that later in 2010,

Technology Transplant will have another batch of pots which solve the

shaft length problem by having an extended frame at the bottom.

This

should work fine.

In the mean-time, from August 2010 onwards, I am using the above pots,

with their shorter shafts, and boosting their mounting position with

some 1.6mm thick phenolic paperboard spacers I had laser cut.

We are very fortunate that Technology

Transplant has these pots manufactured, and sells them

world-wide.

This is an obscure pot-shape, and ALPS haven't made this kind of pot

since the early 1980s.

The values of the pots are:

- Tuning: 50K B (Linear).

- Cut Off: 50K A (Logarithmic curve on anticlockwise end).

- Resonance: Dual 50K B (Should be linear, but replacement pots

have a log curve at both ends).

- Env Mod: 50K A (Logarithmic curve on anticlockwise end).

- Decay: 50K A (Logarithmic curve on anticlockwise end).

- Accent: 50K B (Linear).

The original parts are no-doubt unobtainable, but here are the Roland

part numbers anyway:

- Tuning and Accent pots: 50K linear

(Marked

underneath

as

"50KB"). Roland part number 13219331.

- Cut Off and Env Mod pots: 50K log ("50KA"). Roland

part

number

13219340.

- Resonance pot: Dual 50K linear ("50KBX2").

Roland

part number

13219775 (not the 13219774 mentioned in the service

manual).

- Decay pot. 1 meg linear ("1MA").

Roland part

number

13219339.

To help with debugging, the

following diagram shows the connections and function of the Resonance

pot:

3 - General maintenance

Here are a few tips on keeping your TB-303 healthy, and in reassembling

it.

3.1 - Never spray anything in the machine

Do not under any circumstances spray anything, such as WD-40,

contact

cleaner etc. into any item of electronic apparatus.

If pure water gets into the machine, due to rain or some other

source,

just let it dry. If there is lots of water, pull it apart and mop

it

up with tissues before letting it dry in warm air. The ALPS 24 tact

switches

will

not like being immersed in anything – but they may survive

water.

But how could they dry properly, since the actuator is closed against

the

retaining ring except when it is pressed? (Omron tact switches

are supposed to be sealed against liquid and dust, so they should not

be affected by liquids, unless they contain sugar and so gum up the

movement of the plunger.)

If some sticky liquid gets

into a machine, open it up and wash it away with warm water, using a

toothbrush

and maybe just a little detergent. Then let it dry in warm

air.

Best replace the ALPS tact switches!

3.2 - Overheated Q45 power transistor

Sometimes, presumably due to application of more than 9 volts, the

power

transistor Q45 may be brown or defective. I replace them with a

relatively

common PNP transistor called a TIP30. (Farnell

Electronic Components

has them). Whatever you use, make sure it has

the

pin functions, left to right, of Base, Collector and Emitter. The

TIP30 has the same connections. The TIP30's beta (hFE, AKA

current gain) may not

be as good as the original 2SB596 transistor. The TIP30A spec

sheet from Multicomp from Farnell quotes minimum beta of 40 for 0.2A at

4 volts VCE. However the minimum is only 15 for 1A at 4 volts

VCE. The 2SB596 datasheet from:

http://www.ortodoxism.ro/datasheets/WINGS/2SB596.pdf quotes a minimum

beta of 40 for 1A with 5V VCE.

I picked those transistors which required

less than1.5mA and put a 2.2k across R167, to boost the base current at

lower voltages.

The

Devil Fish requires more power than the TB-303, due to the MIDI In

system, the other circuitry and the three LEDs in the Devil Fish panel,

and for MIDI, the Blue LED too. The 1.5k R167 would

only have about 2.4 volts across it - 1.6mA (assuming there was no

voltage drop in R168 and Q44) when the input voltage is 9 volts.

Actually, this is the voltage with 9.5 volts going into the

machine and with R168 shorted and 1K across R169 (Devil Fish 4.0C and

later). So without these mods and with a genuinely 9 volt supply,

the voltage across R167 would be more like 1.5 volts and the base

current only about 1mA. We need a transistor with a beta of 180

or more when running with a collector current of about 180mA .

I

tested a batch of MOSPEC TIP30As to see what base current I

needed to get 200mA Ic with about a 4 volt VCE. The best was

1.02mA and the worst was 3.58mA. The 2SB596 needed 0.94mA, which

is a beta of over 200.

3.3 - Pinched wires during re-assembly

It is very easy to pinch various wires when re-assembling the machine –

especially

black wire 28 near the output socket. Replace any wires which have been

pinched

and exercise care when re-assembling

The Devil Fish has many more

wires. If you dismantle one, please be very careful re-assembling

it.

3.4 - Knobs falling off

A little piece of "Blu-Tack" (grey

putty-like stuff for putting posters on walls and a vast array of other

crucial tasks:

http://en.wikipedia.org/wiki/Blu-Tack

) is the best solution I have found. Never glue the knobs in

place. They must be removed for installation and maintenance of

the Devil Fish.

Keep an eye out for loose nuts on the tempo and volume pots.

I find that the shafts of the two rotary switches can vary somewhat. If

you take off their knobs, it is best to mark them so they can be placed

back on the same switch. The same applies to the Tempo and Volume

pots, which have very different shafts.

3.5 - Noisy volume pot

The original ALPS volume pots, with

integral power switch, rarely fail. However, over the years, they

can become noisy when turned.

I fix this by desoldering the pot and prising the back off it, by

bending back four lugs which wrap around the front face of the

pot. Then I clean the conductive tracks and the wipers -

especially the two inner wipers to the rotor's slip-ring - with

isopropyl alcohol and some thin cardboard. I spin the rotor

around clockwise. Doing it anticlockwise could cause the wiper to

jam against the metal strip in the middle of the zone it does not

normally travel in.

In my experience, this always fixes the noise problem.

Technology Transplant have replacement Volume pots, but I generally

keep the ALPS pot, after cleaning it, in part because the ALPS pot

shafts fit the knob perfectly, while I find the Technology Transplant

shafts may be somewhat too big.

In my experience there is very little trouble with the Tempo pot,

probably because most people sync their machines externally, rather

than using the internal oscillator. Tempo pots can be cleaned as

described above. Technology Transplant make replacement Tempo

pots too.

I have received a report from a customer who

fixed a noisy Resonance pot by

placing a drop of DeoxIT Fader Cleaner inside the pot. I am not

sure whether he used the spray which is only 5% or the needle dispenser

form, which is 100%. I guess the latter. Nor do I know how

long the fix lasted for. I have never used these materials but

they seem to get a good rap in various discussion forums. Other

companies make liquids and sprays for rotary pots, carbon or conductive

plastic and for linear faders, which have special lubrication

requirements. There are a large number of different DeoxIT

products. This is the page for DeoxIT Fader Cleaner:

3.6 - Batteries not connecting

Early TB-303s had a positive battery connector which was rather

thin - too thin for modern batteries whose positive terminal does not

stick out very far.

Later

ones were pressed differently and were a few mm more towards the

positive

end of the battery. Simply remove the old battery connector and form

(IBM

Selectric service instructions use the term "form" instead of "bend")

the

edges of the connector so the contact area sticks out a little more.

The negative spring connector can be a problem too – especially

when

it has been subject to corrosion from leaking batteries. Remove it from

the

machine, wash any corrosive materials and rust from it and file the end

to

expose fresh steel.

The wires to these connectors often fracture after several

assembly-reassembly

cycles, because the wire is impregnated with solder. Simply trim back

the

wires and re-solder them.

Technologytransplant.com

now sell a kit with replacement battery contacts (very nicely made,

including the negative contact spring) and a new battery compartment

cover.

3.7 - Memory problems - corrosion of RAM chip pins

I describe this problem in terms of the TB-303, but the same problem

would occur in the TR-606 as well.

On many occasions (probably 20 or 30, from the early 1990s to 2010), I

have encountered an extraordinary fault: severe

corrosion

of pin 18 (power) and pin 10 (/WE) of the 1K x 4 static RAM

chips.

This could cause all sorts of memory problems, including the inability

to write new patterns correctly.

I used to think this is only a problem if there has been traces of

corrosive battery

material

in the case for long periods of time. However, I have now seen

this corrosion in machines where there is absolutely no evidence of

battery leakage. Therefore, I think the corrosive atmosphere is

created by the batteries themselves - but probably only if the machine

is left in a tightly sealed container for a long period of time, such

as several years.

The corrosion only occurs on those pins which are at +5 volts from the

battery

supply. (Actually, it can be more like 5.5 volts!). Perhaps not

every type

(manufacturer)

of memory chips is affected. The pin is typically visibly

"rusty", but in some cases, it

looked

to be in quite good condition, despite being completely corroded inside

the

plating, and not making reliable contact.

The worst corrosion appears to occur inside the pin at about the level

of the phenolic PCB - just inside the hole. Pressing firmly,

sideways, on the pin with a screwdriver will reveal the corrosion: the

pin will bend and buckle, or perhaps fall away.

These low-power CMOS 1K x 4 chips have not been manufactured since the

early 1980s. Please do not replace them with 2114s which have a

high current drain and are not suitable for battery backup.

(I can supply these chips, as removed from working machines, and

checked to ensure they have no pin corrosion.)

The functions of the three memory chips, left to right, are:

- IC3: Patterns of Pattern Group I and II.

- IC4: Patterns of Pattern Group III and IV.

- IC5: Pattern edit buffer and Tracks

3.8 - Buzzing due to LED activity

Here is something I discovered in January 2012 and have been doing to all the machines I work on since then.

Some, many or all TB-303s have a low-level buzz in the background,

irrespective of the Volume pot setting. While this is well below

ordinary signal levels, it might be annoying. The buzz from LED

activity – especially with four LEDs on at once, such as when selecting

patterns 1, 2, 3 and 4 – is apparent when running from batteries.

A higher frequency buzz, from the Interrupt oscillator, may be audible

when running from an external power adaptor. The lower frequency

buzz problem seems to be most apparent with the original LEDs or

perhaps with any Red LEDs. Blue LEDs have a higher threshold

voltage and draw less current.

The cause is ground loop problems within the machine. The fix is

to install a wire (such as a multi-strand piece of hookup wire) between

the Output socket ground terminal and the ACW (ground) terminal of the

Volume pot.

4 - Modifications

Here are a few mods which you can do with little trouble to a TB-303.

There

is no discount for subsequent Devil Fish mods to a machine with these

mods

– which represent a small proportion of the complete set of

modifications.

These instructions are given on the understanding that they will

be

carried out by someone with some electronic expertise. Don't do

them if

you are unsure of yourself and don't email me for support if you get

into

trouble. If you get into trouble doing these simple things then you

should

have recognised that you lacked even the most basic expertise.

4.1 - Increasing the range of the Cut Off and Env

Mod pots

To increase the high range of the

Filter Cut Off pot, turn TM3 (near

the mode

switch) clockwise.

To provide a lower limit to the range of frequencies, without

altering

the high limit, short out R47 - a 10K resistor just to the left of the

Env

Mod pot. Do this short with a small length of insulated wire on the

rear side

of the PCB.

To triple the high range of the Env Mod

function, solder a 100 K

resistor

to the back of the board in parallel with R63 - a 220K. R63 is driven

by

the wiper of the Env Mod pot and is located directly adjacent to the

wiper

pin of the pot. Put the resistor on the rear side of the board. I use a

1/8

watt miniature resistor, but you should be OK with a standard 1/4 W.

To extend the range of the Env Mod pot to include zero envelope

modification,

then short out R61 (10K) which is located logically and physically to

the

anti-clockwise pin of the Env Mod pot.

4.2 - Improving the bass response

The standard TB-303 has a weedy bass response. The culprits are C20 and

C21

– both 0.01 uF. Take these out and replace them with 0.1 uF capacitors.

I

use monolithic ceramic caps because they are compact. It does

not

matter that mono caps have a wide capacitance tolerance and a lousy

temperature

co-efficient. This is a non-critical value and anything around 0.1 uF

is fine.

This gives a worthwhile improvement in bass response. If you want

to

restore the original TB-303 sound, just do it externally with EQ.

Update history:

- 1996 September 15: Original version.

- 2001 January: To cover replacing the pots.

- 2001 March 13: Reliability in general

- 2001 April 22: Fixed mention of resonance pot - should be linear.

- 2002 April 26 and 28: Mentioned the newly manufactured

replacement

pots, some other replacement parts and corrected my mention of the

Decay pot

to be log, rather than linear.

- 2002 May 2: More information about the shaft-length of the six

pots,

and the difficulty of fitting the knob on the new Resonance pot.

- 2002 May 26: Updated Rob Cyborgzero's email address.

- 2002 August 24: Updated Rob's web site, report on his translucent

knobs

and wrote some more about replacement pots. (He only did this

briefly, so I later deleted this material.)

- 2004 August 5: Updated contact details for

http://www.technologytransplant.com . Updated reliability

information on dust-guard protected switches. Various other updates.

- 2005 August 25: Added note about restricted active rotational

range of replacement Resonance pots.

- 2007 August 21: Linked to Mouser rather than Farnell for SKHCAA.

- 2007 November 20: Notes on beta of TIP30A.

- 2008 January 27: Pointer to new page on the 6 small pots.

- 2010 January 3: Updated links to Technologytransplant.biz (for a

while they were not at .com) and

deleted information which is either obsolete or better covered by the

pot-wear/ page.

- 2010 August 27: Complete revision to cover the 2009 - 2010

batches of Technology Transplant 6 small pots, and mods to Omron tact

switches. Technology Transplant URLs changed back to

technologytransplant.com .

- 2010 September 2: Added initial measurements of tact switch

hysteresis.

- 2010 September 5: Replaced these initial measurements with a new

page of much more detailed force and displacement measurements: ../tact-switches/ .

- 2013 November 24: Added note that the pots from

Technology Transplant are different now. Added section on

reducing LED noise. Added note to the Noisy Volume Pot section on

DeoxIT Fader Cleaner.

© Robin Whittle 1996 to 2013 – First Principles and Real World Interfaces

Return to the main Devil Fish page.